Do you require accurate cost estimation for your aluminum castings? Look no further! Our Aluminium Casting Cost Calculator helps in instant and cost-effective estimation of the production costs associated with die casting aluminium. It is extremely simple to use, all you have to do is enter some details about your specific casting requirements and you can get an estimated cost right away.

Table Of Content:

- Die Casting Cost Estimator

- How to Calculate Die Casting Cost | RapidDirect Blog

- Sand Casting Aluminum Parts compared to Aluminum Die Castings

- China Die Casting Price Quote

- Calculating Die Casting Prices |

- Early Cost Estimation of Die Cast Components

- Casting cost estimation in an integrated product and process design ...

- Investment Casting Cost Estimates | KI Castings

- Aluminum Weight Calculator

- How To Calculate The Price Of Die Casting Parts And Molds ...

1. Die Casting Cost Estimator

https://www.custompartnet.com/estimate/die-casting/

Custom Die Casting part cost estimator. Build your own complete process plan and generate detailed cost estimates. Invite colleagues or customers to ...

2. How to Calculate Die Casting Cost | RapidDirect Blog

https://www.rapiddirect.com/blog/die-casting-cost/ Mar 26, 2022 ... Die Cast Mold Design. A simple design will lower die casting costs. However, you can't simply choose a simple design if it doesn't relate to ...

Mar 26, 2022 ... Die Cast Mold Design. A simple design will lower die casting costs. However, you can't simply choose a simple design if it doesn't relate to ...

3. Sand Casting Aluminum Parts compared to Aluminum Die Castings

https://www.kineticdiecasting.com/sandcasting.html Aluminum sand cast tooling costs from $500 to $7,500 depending on size and complexity of the aluminum casting part life is 5,000 parts. Aluminum die casting ...

Aluminum sand cast tooling costs from $500 to $7,500 depending on size and complexity of the aluminum casting part life is 5,000 parts. Aluminum die casting ...

4. China Die Casting Price Quote

http://www.sourcing-cn.com/diecasting/ Feb 1, 2012 ... Molding Machine Tonnage Calculation (Optional, we have already chosen the typical parameters.) Formation Pressure (click here for details).

Feb 1, 2012 ... Molding Machine Tonnage Calculation (Optional, we have already chosen the typical parameters.) Formation Pressure (click here for details).

5. Calculating Die Casting Prices |

https://www.kineticdiecasting.com/kdc/calculating-die-casting-prices/ Jun 5, 2017 ... Kinetic Die Casting Part Pricing – How Die Casting Part Prices are ... material cost, which also relates to the die casting material type.

Jun 5, 2017 ... Kinetic Die Casting Part Pricing – How Die Casting Part Prices are ... material cost, which also relates to the die casting material type.

6. Early Cost Estimation of Die Cast Components

https://digitalcommons.uri.edu/cgi/viewcontent.cgi?article=2501&context=thesesBlum, Carolyn, "Early Cost Estimation of Die Cast Components" (1989). ... used to calculate ... estimate. ~actual. Figure 3.38: Comparison of Estimated.

7. Casting cost estimation in an integrated product and process design ...

https://www.tandfonline.com/doi/pdf/10.1080/09511920500324605green sand casting, investment casting or gravity die casting), ... expected to estimate accurately casting costs, especially for new products.

8. Investment Casting Cost Estimates | KI Castings

https://kicastings.com/investment-casting-cost-estimates/ The initial cost of the metal plays a big role in the final estimate for total production. If you're not sure which material is right for your project, review ...

The initial cost of the metal plays a big role in the final estimate for total production. If you're not sure which material is right for your project, review ...

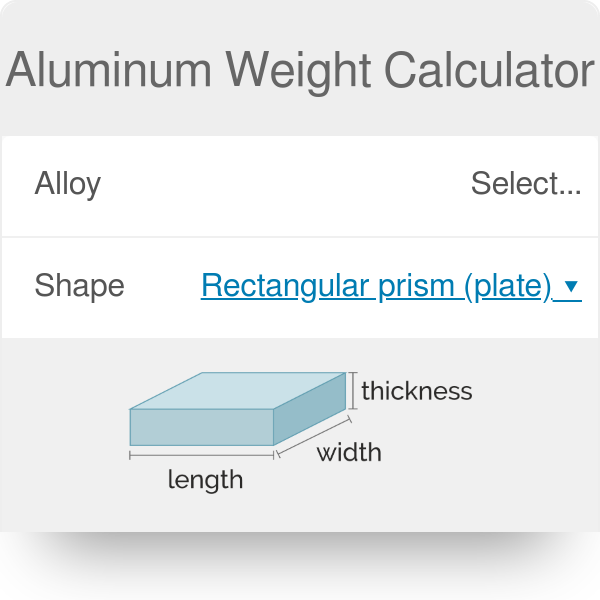

9. Aluminum Weight Calculator

https://www.omnicalculator.com/construction/aluminum-weight Apr 6, 2022 ... How to calculate aluminum weight? Aluminum alloy chart; What is aluminum and where is it used? With this aluminum weight calculator, you can ...

Apr 6, 2022 ... How to calculate aluminum weight? Aluminum alloy chart; What is aluminum and where is it used? With this aluminum weight calculator, you can ...

10. How To Calculate The Price Of Die Casting Parts And Molds ...

https://www.diecastingcompany.com/helpful-articles/how-to-calculate-the-price-of-die-casting-parts-and-molds Empirical Calculation Method. Mould price = material cost + design fee + processing fee and profit + value-added tax + mold trial fee + packaging and ...

Empirical Calculation Method. Mould price = material cost + design fee + processing fee and profit + value-added tax + mold trial fee + packaging and ...

What does the Aluminium Casting Cost Calculator do?

The Aluminium Casting Cost Calculator helps provide instant and cost-effective estimates of the production costs associated with die casting aluminium. It is a user-friendly online tool that allows users to quickly get an estimated cost for their aluminum castings without any complications.

How do I use the Aluminium Casting Cost Calculator?

To use the Aluminium Casting Cost Calculator, simply enter your required specifications into the form, such as volume, wall thickness, material type etc., then hit ‘Calculate’ and you will get an estimated value for your casting project.

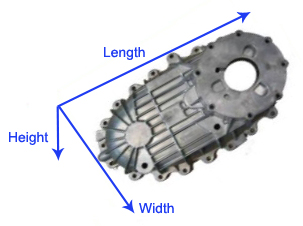

What information needs to be provided for calculating casting costs?

The key information needed for calculating casting costs includes cavity number, weight per piece, parting line surface area and runner design. Additionally, other factors such as location of delivery, labour rates and raw material prices also need to be taken into account when estimating total production costs.

What kind of materials can be used with this calculator?

Currently the Aluminium Casting Cost Calculator supports two types of materials – ADC12 (Aluminum Die Cast) and AC4C (Aluminum Cast Alloy). However it should also be noted that more materials may be added in future based on customer demand.

Conclusion:

The Aluminium Casting Cost Calculator provides a quick and easy way to estimate production costs associated with aluminum castings without spending unnecessary time or money on traditional methods. This online calculator is simple to use - just enter your required specifications into the form and within moments you will have access to accurate estimates of your aluminum casting project's total costs.