3D printing is quickly becoming a popular way to create custom-made items and prototypes. With 3D printing, it’s possible to create intricate objects with accuracy and precision without having to use traditional manufacturing processes. One of the most common questions people have about 3D printing is the cost per cubic inch. Knowing this cost can help you budget for your project effectively and will give you an idea of how much material you will need.

Table Of Content:

- How Much Does 3D Printing Cost? - 3 Space

- How To Compare The Real Cost of Filaments for 3D Printing

- How To Compare The Real Costs Of 3D Printing Filaments « Fabbaloo

- How to Price 3D Printing Service Fees – ACRL TechConnect

- How much does 3D printing cost? [2021 Update] - PrintAWorld

- Clearing Up the Hype Behind 3D Printing - Axis Blog Post

- How Determine 3D Printing Cost Accurately For Your Designs ...

- Material cost for printing – ToyBuilder Labs

- How Much Does a 3D Print Job Cost?

- How to determine 3d printing cost per cubic inch without designing a ...

1. How Much Does 3D Printing Cost? - 3 Space

https://3space.com/how-much-does-3d-printing-cost/ Jun 17, 2019 ... The average cost for thermoplastic model filament will range from $3.50 to $7.50 per cubic inch. Because FDM printers require the use of support ...

Jun 17, 2019 ... The average cost for thermoplastic model filament will range from $3.50 to $7.50 per cubic inch. Because FDM printers require the use of support ...

2. How To Compare The Real Cost of Filaments for 3D Printing

https://3dprinting.com/filament/how-to-compare-the-real-cost-of-filaments-for-3d-printing/ Dec 11, 2016 ... What really matters in calculating the costs of printing is the cost per volume of print; ie cubic inch or cubic centimeter.

Dec 11, 2016 ... What really matters in calculating the costs of printing is the cost per volume of print; ie cubic inch or cubic centimeter.

3. How To Compare The Real Costs Of 3D Printing Filaments « Fabbaloo

https://www.fabbaloo.com/2016/04/how-to-compare-the-real-costs-of-3d-printing-filaments Apr 10, 2016 ... To convert to cubic inches, multiply 12.5 US cents x 16.39 cubic cm/ cubic inch = $2.05 per cubic inch for this particular USD$78 spool of ...

Apr 10, 2016 ... To convert to cubic inches, multiply 12.5 US cents x 16.39 cubic cm/ cubic inch = $2.05 per cubic inch for this particular USD$78 spool of ...

4. How to Price 3D Printing Service Fees – ACRL TechConnect

https://acrl.ala.org/techconnect/post/how-to-price-3d-printing-service-fees/ May 22, 2017 ... Examples – 3D Printing Service Fees · 2014 – $7.20 per cubic inch of modeling material (raised to $8.45 starting July, 2014). · 2017 – uPrint – ...

May 22, 2017 ... Examples – 3D Printing Service Fees · 2014 – $7.20 per cubic inch of modeling material (raised to $8.45 starting July, 2014). · 2017 – uPrint – ...

5. How much does 3D printing cost? [2021 Update] - PrintAWorld

https://prtwd.com/guides/how-much-does-3d-printing-cost/![How much does 3D printing cost? [2021 Update] - PrintAWorld](https://images.ctfassets.net/dovsnf6qrcem/71euFz7gTNGZIhukYaNybp/dffec7a81f89b3641b83d70b3956a8ec/mmexport1559995535068.jpg) If you're 3D printing at home, then those factors are your material, electricity and 3D printer cost. But if you're looking for a 3d printing service or ...

If you're 3D printing at home, then those factors are your material, electricity and 3D printer cost. But if you're looking for a 3d printing service or ...

6. Clearing Up the Hype Behind 3D Printing - Axis Blog Post

https://www.axisproto.com/blogs/clearing-up-the-hype-behind-3d-printing/ Plastic material for a 3D printer costs about 84 cents per cubic inch, which is significantly more, by the same unit of measure, than the cost of a finished ...

Plastic material for a 3D printer costs about 84 cents per cubic inch, which is significantly more, by the same unit of measure, than the cost of a finished ...

7. How Determine 3D Printing Cost Accurately For Your Designs ...

https://blogs.truventor.ai/blogs/3d-printing-cost-per-cubic-cm-inch/ To keep it simple, consider the rate of 3D printing to be INR 100 / cubic centimetre or approx. INR 1638 / cubic inch. Which means for 1 customary cup (ie.

To keep it simple, consider the rate of 3D printing to be INR 100 / cubic centimetre or approx. INR 1638 / cubic inch. Which means for 1 customary cup (ie.

8. Material cost for printing – ToyBuilder Labs

https://www.toybuilderlabs.com/blogs/news/13055597-material-cost-for-printing Dec 14, 2013 ... But, I didn't break down the cost of plastic per volume in that post. ... the really short answer is "about a dollar per cubic inch".

Dec 14, 2013 ... But, I didn't break down the cost of plastic per volume in that post. ... the really short answer is "about a dollar per cubic inch".

9. How Much Does a 3D Print Job Cost?

https://www.jawstec.com/2019/02/20/3d-printing-cost/ Feb 20, 2019 ... 3D printing pricing is similar to that of other manufacturing techniques in a number of ways. Both the materials and the process have purchase ...

Feb 20, 2019 ... 3D printing pricing is similar to that of other manufacturing techniques in a number of ways. Both the materials and the process have purchase ...

10. How to determine 3d printing cost per cubic inch without designing a ...

https://medium.com/@yashrane/how-to-determine-3d-printing-cost-per-cubic-inch-without-designing-a-cad-e794de55eca INR 1638 / cubic inch . (I am assuming this cost to obtain a decent quality prototype. You will find companies quoting as low as INR 5 / cubic centimeter to INR ...

INR 1638 / cubic inch . (I am assuming this cost to obtain a decent quality prototype. You will find companies quoting as low as INR 5 / cubic centimeter to INR ...

What factors contribute to the cost per cubic inch?

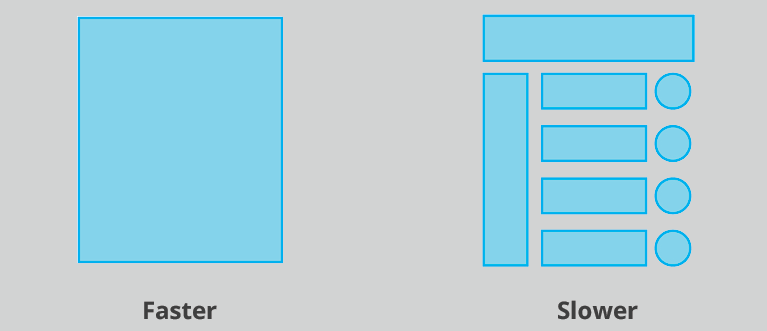

The biggest factors that contribute to the cost per cubic inch include the type of 3D printer being used and the type of material that is being printed with it. Different types of printers may require different filament types or may print at different speeds which can lead to differences in cost per cubic inch. Additionally, certain materials may be more costly than others so this should also be taken into consideration when calculating costs.

Is there any way to reduce 3D printing costs?

Yes, there are a few ways to reduce 3D printing costs. First, make sure that you plan your design carefully before beginning the printing process so that it prints as efficiently as possible. Second, consider using lower cost materials if available for your project. Additionally, look into different types of printers and compare them on quality versus price so you can get the best value out of your purchase.

Are there any other costs associated with 3D printing?

Yes, there are additional costs associated with 3D printing such as shipping fees for filament or software purchases which can add up over time. Additionally, some projects may require post-processing such as sanding or painting which will increase overall project costs.

How long does it take to print something in 3D?

This depends on the complexity of the project but generally speaking most small projects can be completed in a few hours while larger more detailed projects may take days or weeks depending on size and detail needed.

What kind of materials can be used for 3D Printing?

There are many different types of materials available for use in 3d printing including plastics such as ABS or PLA, metals such as aluminum or stainless steel, ceramic composites such as Porcelainite, wood composites like Woodfill, rubber-like elastomers like TPE/TPC/TPV/TPE+, nylon filaments like NylonX & NylonG, waxes like HIPS Wax among others.

Conclusion:

Understanding what goes into calculating 3d Printing Costs Per Cubic Inch helps ensure that projects have accurate budgets allocated beforehand allowing users to maximize their investment towards a successful outcome. It's important to understand all associated costs from initial purchasing prices through shipping & post processing in order to make wise investments given your individual needs & circumstances.