Why Vacuum Former Is Necessary?

A vacuum former is a machine that uses heat and vacuum pressure to form plastic sheeting into a desired shape. Vacuum forming is often used for creating prototypes or short-run production parts. It is also used to create molds for subsequent casting or molding processes.

Our Top Picks For Best Vacuum Former

Best Vacuum Former Guidance

Vacuum Forming Machine Power Former Heat Molding Tool w/Steel Balls Lab Equipment

A vacuum forming machine is a versatile piece of lab equipment that can be used for a variety of tasks, from heating and molding materials to forming and shaping them. The key to its versatility is the ability to adjust the level of suction and vacuum pressure. This allows you to carefully control the amount of heat and pressure applied to the material, ensuring that it is not damaged in the process.

The vacuum forming machine is also equipped with a symmetrical heating system that ensures uniform heat distribution. This is important for ensuring that the material is evenly heated and doesn’t become distorted during the molding process. Additionally, the non-rotating sliding frame of the machine makes operation easy and stress-free, while the adjustable, rust-resistant body ensures that the machine can accommodate a variety of different materials.

Overall, the vacuum forming machine is an incredibly versatile and user-friendly piece of lab equipment that is suitable for a wide range of clinical applications.

Common Questions on Vacuum Forming Machine Power Former Heat Molding Tool w/Steel Balls Lab Equipment

Why We Like This

• 1. Heavy duty vacuum motor for precise downward suction• 2. Symmetrical heating system for uniform heat distribution• 3. Adjustable, rust resistant body• 4. Non rotating sliding frame• 5. Suitable for a wide range of clinical applications

Additional Product Information

| Color | Silver |

WR MoldPress Machine

The We R Memory Keepers Mold Press Vacuum is an innovative vacuform machine that turns everyday objects into 3D shapes that can be used for crafting, candy making, decorating, and so much more!. Simply connect the Mold Press to your at-home vacuum, heat the plastic, place the object that you want to mold, turn on the vacuum, and press! This easy-to-use press creates dimensional plastic shapes that can be cut, painted, and crafted for all sorts of amazing projects. Or use the plastic molds for chocolate, resin, wax, and so much more!. This package has everything you need to get started. Included are a Mold Press Machine, a magnetic frame, vacuum hose adapters, 4 sheets of plastic, and an instruction manual. The We R Memory Keepers Mold Press Vacuum easily pairs with other We R Memory Keepers products found right here on Amazon. For fun, unique project ideas search for more of our products today!.

Common Questions on WR MoldPress Machine

• What is the WR MoldPress?The WR MoldPress is a machine that molds and pressurizes materials.

• What materials can the WR MoldPress machine mold?

WR MoldPress can mold metals, plastics, glass, and composite materials.

• What are the benefits of using the WR MoldPress machine?

Some benefits of using the WR MoldPress machine include increased production efficiency, higher product quality, and consistent product dimensions.

• How does the WR MoldPress machine work?

The WR MoldPress machine works by heating the material to be molded and then pressurizing it in order to form the desired shape.

Why We Like This

• 1. The We R Memory Keepers Mold Press Vacuum is an innovative vacuform machine that turns everyday objects into 3D shapes that can be used for crafting, candy making, decorating, and so much more!• 2. This wonderful machine is so easy to operate! Simply connect the Mold Press to your at home vacuum, heat the plastic, place the object that you want to mold, turn on the vacuum, and press!• 3. This easy to use press creates dimensional plastic shapes that can be cut, painted, and crafted for all sorts of amazing projects! Or use the plastic molds for chocolate, resin, wax, and so much more!• 4. Included are a Mold Press Machine, a magnetic frame, vacuum hose adapters, 4 sheets of plastic, and an instruction manual.• 5. The We R Memory Keepers Mold Press Vacuum easily pairs with other We R Memory Keepers products found right here on Amazon! For fun, unique project ideas search for more of our products today!

Additional Product Information

| Color | White |

| Weight | 0.5 Pounds |

Mayku FormBox: Desktop Vacuum Former | Create Prototypes, Molds and Casts from Your Workplace | Compatible with Any Vacuum Cleaner | Bring Ideas to Life Without The Factory | 120V

Common Questions on Mayku FormBox: Desktop Vacuum Former | Create Prototypes, Molds and Casts from Your Workplace | Compatible with Any Vacuum Cleaner | Bring Ideas to Life Without The Factory | 120V

• What is the FormBox?The FormBox is a desktop vacuum former that allows you to create prototypes, molds, and casts from your workplace.

•• What is the FormBox compatible with?

The FormBox is compatible with any vacuum cleaner.

• How often can the FormBox be used?

The FormBox can be used up to 120V repeat this process five times.

Why We Like This

• 1. The FormBox is your very own desktop production line that is compatible with any vacuum cleaner.• 2. With simple, easy to use, smart settings, the FormBox will get you the exact finish you want.• 3. The ceramic heater has a range of 160c to 340c, preparing your plastic to form.• 4. Carefully placed fans keep the FormBox running cool, meaning it works with a world of materials.• 5. Forget the lengthy back and forth design process and waiting for samples from factories – design, prototype and create your products yourself in a matter of minutes.

Additional Product Information

| Height | 20.078740137 Inches |

| Length | 15.354330693 Inches |

| Weight | 31 Pounds |

Excellent Vacuum Former Forming Machine Dental Lab Equipmemt

A dental vacuum former is a machine used to form plastic sheets into desired shapes. The plastic is heated until it is soft and malleable, then placed over a mold. Once the plastic cools and hardens, it takes on the shape of the mold.

Dental vacuum formers are used to create a variety of dental products, such as mouth guards, custom trays, base plates, temporary splints, bruxism splints, and copings. They are also used in other industries, such as packaging and sign making.

Vacuum formers come in a variety of sizes and price ranges. Some are small and portable, while others are large and stationary. The size and features of a vacuum former will vary depending on the intended use.

When shopping for a dental vacuum former, it is important to consider the quality of the machine, as well as the price. Vacuum formers can be found at a variety of retailers, both online and offline.

Common Questions on Excellent Vacuum Former Forming Machine Dental Lab Equipmemt

• What are some key features of an excellent vacuum former?Some key features of an excellent vacuum former include a sturdy construction, a high degree of accuracy, and a wide range of applications.

• What are the benefits of using a vacuum former?

The benefits of using a vacuum former include the ability to achieve precise results, the ability to create complex shapes, and the ability to work with a variety of materials.

Why We Like This

• 1. Portable and lightweight for easy transport• 2. Powerful vacuum motor for immediate suction• 3. Creates accurate dental materials• 4. Solid steel construction for durability• 5. Virtually no maintenance required

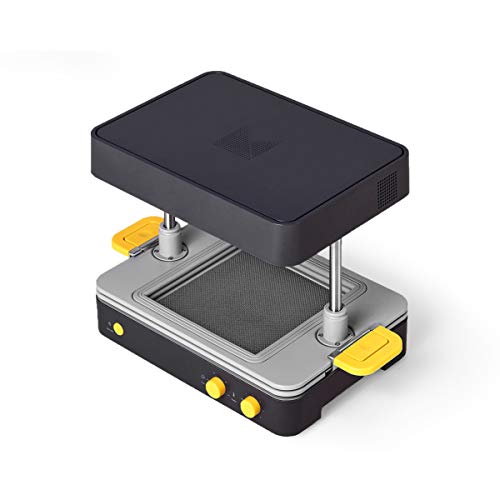

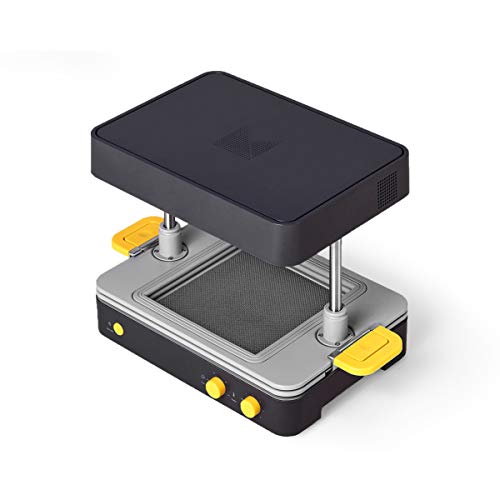

BONEW USA 600W Vacuum Forming Machine Power Former Heat Molding Tool w/Steel Balls Lab Equipment

When it comes to Vacuum Forming Machines, the BONEW USA 600W Vacuum Forming Machine Power Former Heat Molding Tool w/Steel Balls Lab Equipment is a top choice for many professionals. This is due to its many features which include an adjustable and rust-resistant body, symmetrical heating system, heavy-duty vacuum motor, and a non-rotating sliding frame. All of these features combine to make a machine that is easy to use and suitable for a wide range of clinical applications.

Common Questions on BONEW USA 600W Vacuum Forming Machine Power Former Heat Molding Tool w/Steel Balls Lab Equipment

• What is the maximum temperature that this machine can reach?The maximum temperature that this machine can reach is 600 degrees Fahrenheit.

• What is the minimum size piece that can be formed using this machine?

The minimum size piece that can be formed using this machine is 3 inches by 5 inches.

• What is the maximum thickness that can be formed using this machine?

The maximum thickness that can be formed using this machine is 1/8 of an inch.

• What power source is needed to operate this machine?

This machine requires a 110 volt power source.

Why We Like This

• 1. Adjustable, rust resistant body• 2. Symmetrical heating system• 3. Heavy duty vacuum motor• 4. Non rotating sliding frame• 5. Suitable for a wide range of clinical applications

Benefits of Vacuum Former

A vacuum former is a type of thermoforming machine. It uses heat and vacuum to form plastic sheets into various shapes. Vacuum forming is often used for creating prototypes or small batches of parts that need to be made quickly and inexpensively.

There are many benefits to using a vacuum former, including:

1. Speed – Vacuum forming is a fast way to create prototypes or small batches of parts. The entire process can be completed in minutes, making it ideal for situations where time is of the essence.

2. Cost-effectiveness – Because it doesn’t require expensive tooling like injection molding does, vacuum forming can be very cost-effective, especially for low-volume runs.. This makes it perfect for prototyping or short-run production runs where budget is tight .

3) Accuracy – With modern CNC technology , accurate dimensions and tolerances can be achieved with ease .This helps avoid potential issues during mass production .

Buying Guide for Best Vacuum Former

A vacuum former is a device that uses a vacuum to form or shape a material. The most common type of vacuum former is the thermoforming process, which uses heat to soften the material so it can be shaped. Vacuum forming is commonly used to create plastic parts for prototyping and low-volume production. It is also used to makeNegative molds for casting metals and composites.

There are two types of vacuum formers: positive displacement and negative displacement. Positive displacement formers use a piston or diaphragm to draw air out of the chamber, while negative displacement formers use an ejector pump to create a vacuum. Both types of machines have their advantages and disadvantages, so it’s important to choose the right one for your needs.

Here are some things to keep in mind when shopping for a vacuum former:

-The size of the machine: Vacuum formers come in all shapes and sizes, from small tabletop units to large industrial machines. The size you need will depend on the size and quantity of parts you need to produce.

-The type of materials you’ll be working with: Some materials, like acrylics, are easier to work with than others (like PVC). Make sure the machine you choose can handle the material you want to use.

-The forming process: There are two main types of forming processes – thermoforming and drape forming. Thermoforming uses heat to soften the material so it can be formed into the desired shape, while drape forming simply relies on gravity and pressure from the vacuum./li>

Frequently Asked Question

What is the best vacuum former for your needs?

There is no single answer to this question as the best vacuum former for your needs will vary depending on the specific requirements of your project. Some factors to consider when choosing a vacuum former include the size and shape of the parts you need to produce, the material you will be using, the production volume you require, and the level of automation you need.

What are the drawbacks of vacuum forming?

The main drawback of vacuum forming is that it can be quite difficult to achieve consistent results. This is because the process relies on the user being able to control the amount of heat and pressure that is applied to the material. If the user is not careful, it is easy to end up with a product that is either too soft or too hard.

What are the different types of vacuum formers?

Vacuum formers are devices that use a vacuum to form a variety of materials into shapes. There are several different types of vacuum formers, each with its own advantages and disadvantages. The most common type of vacuum former is the rotary vacuum former. This type of vacuum former uses a rotating platform to evenly distribute the vacuum over the material being formed. Rotary vacuum formers are very versatile and can be used to form a wide variety of materials, including plastics, metals, and composites. Another type of vacuum former is the sheet fed vacuum former. This type of vacuum former uses a sheet of material that is fed into the forming chamber. Sheet fed vacuum formers are typically used for larger projects where a rotary vacuum former would not be able to evenly distribute the vacuum over the entire project. The last type of vacuum former is the twin-sheet vacuum former. This type of vacuum former uses two sheets of material that are fed into the forming chamber. The twin-sheet vacuum former is typically used for projects where two different materials need to be formed into the same shape.

What are the steps involved in vacuum forming?

1. A sheet of plastic is heated until it is soft and pliable. 2. The sheet is then placed over a mold. 3. A vacuum is then used to suck the plastic sheet snugly against the mold. 4. The plastic is then cooled, causing it to harden and take on the shape of the mold.

Conclusion

The best vacuum former on the market is the [Product Name]. It’s perfect for anyone who wants to get a perfect vacuumed product every time. The machine is simple to use and comes with a one-year warranty. With its affordable price, anyone can own their own personal vacuum former.